5050 SMD LED Parameter:

|

Color

|

Dominant Wavelength (nm)(k)

|

Luminous Intensity (mcd)(lm)

|

Viewing Angle 50%

|

Forward Current (mA)

|

Forward voltage

(V)

|

Power

(W)

|

|

Blue

|

460-470nm

|

150mcd

|

120°

|

20mA

|

2.8-3.0V

|

0.06W

|

|

Luminous Green

|

510-530nm

|

200mcd

|

120°

|

20mA

|

2.8-3.0V

|

0.06W

|

|

Green

|

570-575nm

|

300mcd

|

120°

|

20mA

|

2.0-2.2V

|

0.04W

|

|

Yellow

|

590-598nm

|

150mcd

|

120°

|

20mA

|

2.0-2.2V

|

0.04W

|

|

Orange

|

600-610nm

|

150mcd

|

120°

|

20mA

|

2.0-2.2V

|

0.04W

|

|

Red

|

620-630nm

|

200mcd

|

120°

|

20mA

|

2.0-2.2V

|

0.04W

|

|

White

|

6000-7000K

|

800mcd

|

120°

|

20mA

|

2.8-3.0V

|

0.06W

|

|

Red+Blue

|

460-470nm

|

150mcd/200mcd

|

120°

|

40mA

|

2.0-2.2V/2.8-3.0V

|

0.1W

|

|

Red+Green

|

460-575nm

|

150mcd/300mcd

|

120°

|

40mA

|

2.0-2.2V/2.8-3.0V

|

0.1W

|

|

RGB

|

460-575nm

|

150mcd/300mcd

|

120°

|

60mA

|

2.0-2.2V/2.8-3.0V

|

0.18W

|

|

Cold White

|

9000K-

|

22-26lm

|

120°

|

60mA

|

2.8-3.2V

|

0.25W

|

|

Warm White

|

2500-3500K

|

22-26lm

|

120°

|

60mA

|

2.8-3.2V

|

0.25W

|

Features

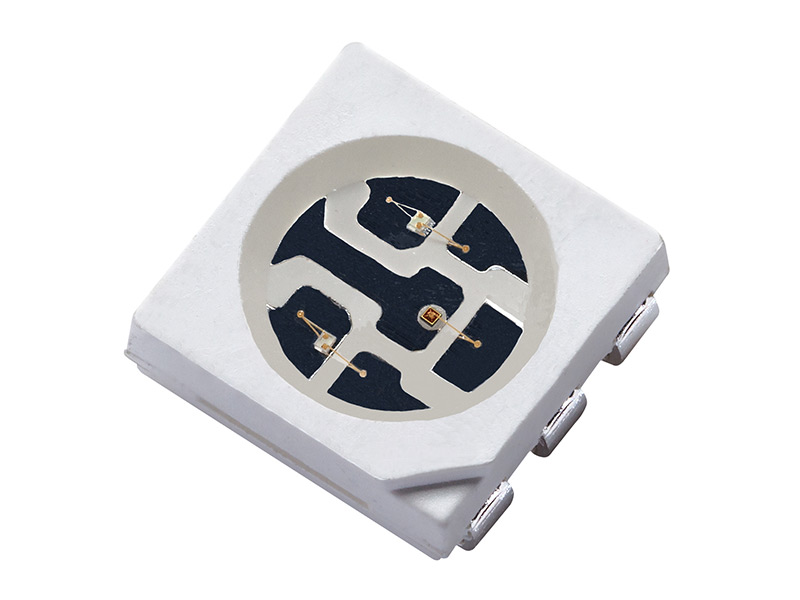

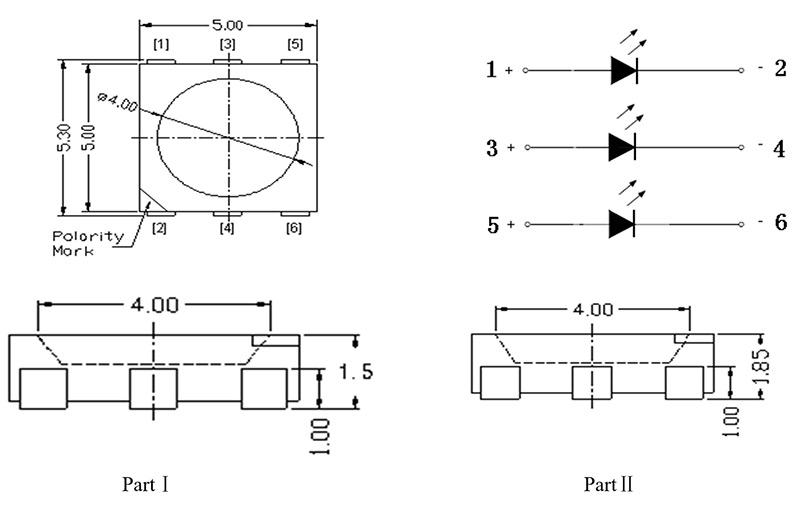

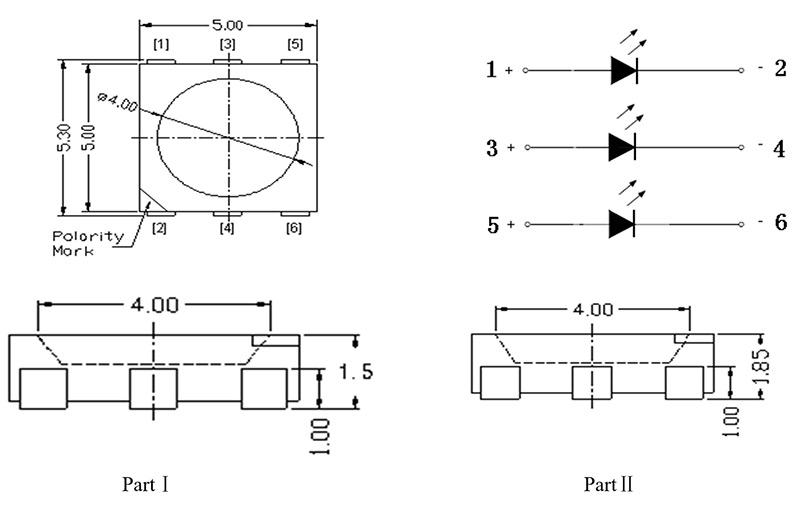

■ Package Size:5.0 (L) × 5.0(W) × 1.85 (T) mm

■ Silicone Packed

■ Suitable for different working environment

■ Super long lifetime:40000HRs

■ Anti UV

■ White colors are available in red、orange、blue、green

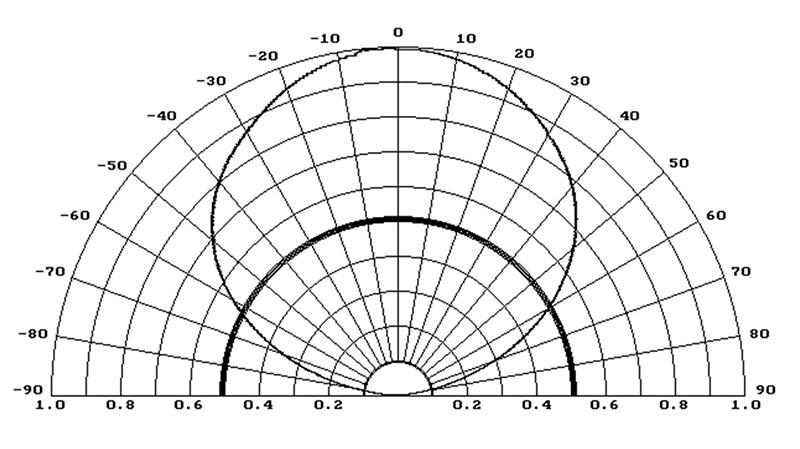

■ Wide viewing angle (2θ1/2=120°)

Applications OF SMD LED 5050

■Indoor lighting:

Fluorescent lamp, tube, bulb etc.

■ Commercial illumination and displays:

Advertising words, light box

■ LCD Backlighting (including LED TV )

■ Decorative lighting: light strip

■ Automotive interior auxiliary lighting: reading lamp

■ Mobile flashlights

■ Luminaries lighting source: Cabinet light, corridor light

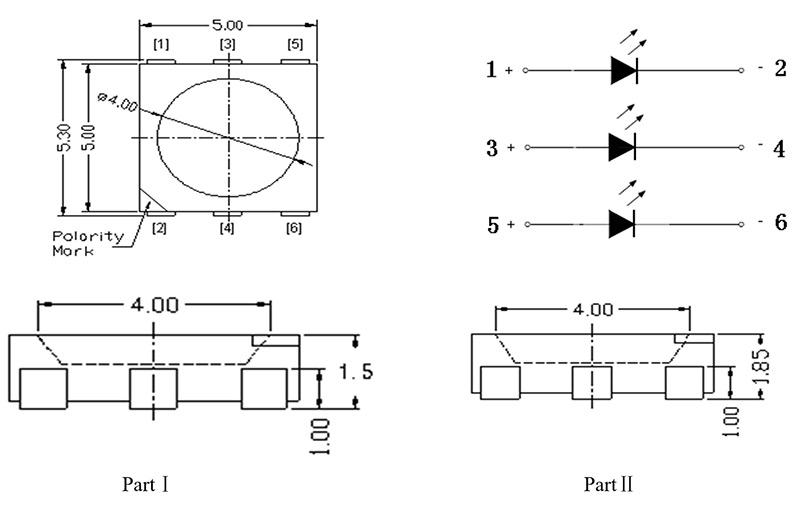

Package Outline Dimension

Remark: PartⅠis our featured product,PartⅡ is the product that is available to provide.

Recommended solder pad for MY-SMD 5050 series

Note: The tolerances unless mentioned is ±0.01 mm.

Absolute Maximum Ratings (Ta=25℃)

|

Parameter

|

Symbol

|

Rating

|

Unit

|

|

Reverse Voltage

|

VR

|

5

|

V

|

|

Forward Current per LED

|

IF

|

25

|

mA

|

|

Operating Temperature

|

Topr

|

-20 ~ +80

|

℃

|

|

Storage Temperature

|

Tstg

|

-20 ~ +80

|

℃

|

|

Soldering Temperature

|

Tsol

|

260(for 5 seconds)

|

℃

|

|

Power Dissipation

|

Pd

|

250

|

mW

|

|

Peak Forward Current

(Duty 1/10 @ 1KHz)

|

IFP

|

300

|

mA

|

Electro-Optical Characteristics(Ta=25℃)

|

Parameter

|

Symbol

|

Min.

|

Typ.

|

Max.

|

Unit

|

Condition

|

|

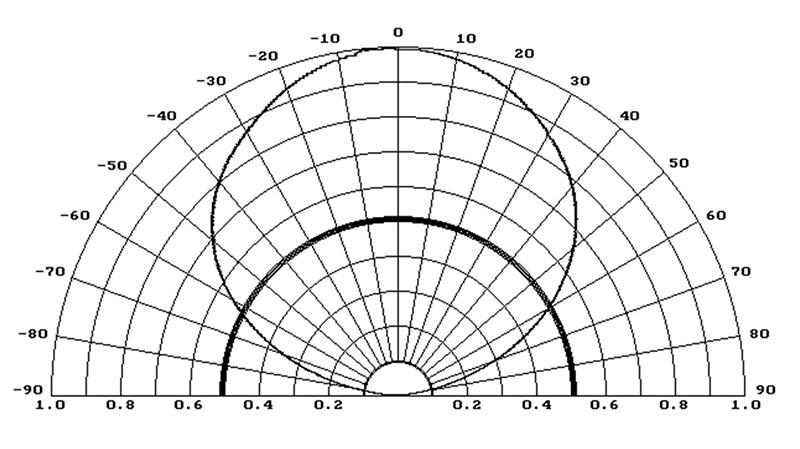

Viewing Angle

|

2θ1/2

|

-----

|

120

|

------

|

deg

|

If=60mA

|

|

Reverse Current

|

IR

|

-----

|

-----

|

50

|

μA

|

VR=5V

|

Notes:

Tolerance of Luminous Intensity is ±15%.

Tolerance of Forward Voltage is ±0.1V.

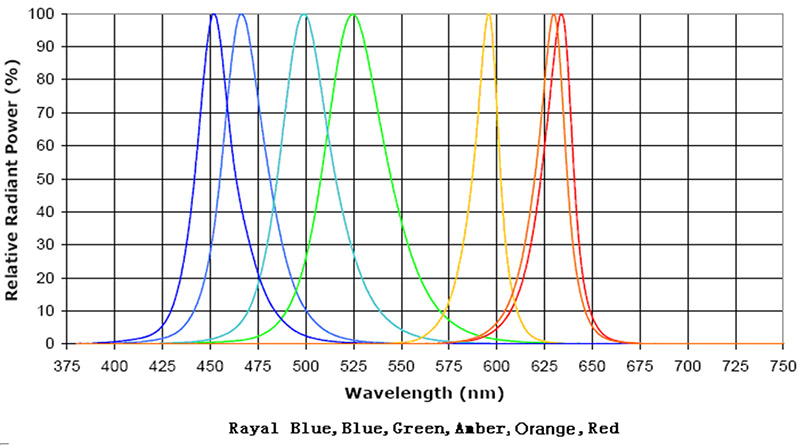

Bin Range of Luminous Intensity

|

Color

|

Dominant wavelength(nm)

λD@ 60mA

|

Forward Voltage(V)

Vf@ 60mA

|

Luminous Intensity(mcd)

IV@ 60mA

|

Part Number

|

|

Min.

|

Max.

|

Min.

|

Max.

|

Group

|

Min.

|

Typ.

|

|

White

|

2000k

|

7000k

|

2.9

|

3.5

|

B1

|

18LM

|

26LM

|

MY-5050W-XX

|

|

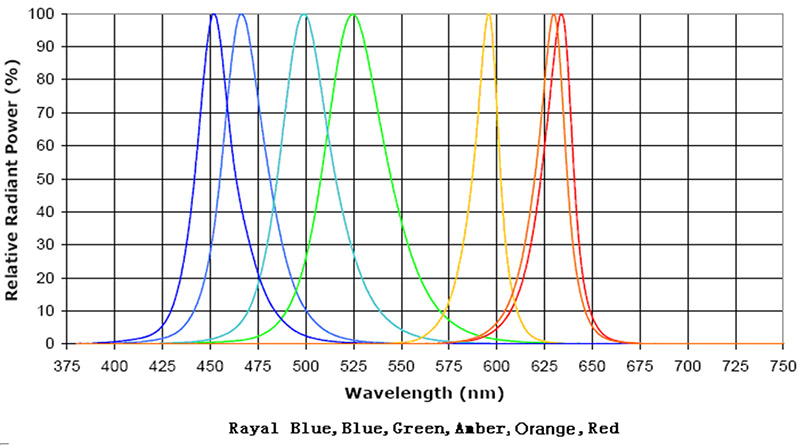

Royal Blue

|

455

|

465

|

2.9

|

3.5

|

C1

|

450

|

600

|

MY-5050RB-XX

|

|

Blue

|

465

|

475

|

2.9

|

3.5

|

C1

|

450

|

600

|

MY-5050B-XX

|

|

Green

|

515

|

535

|

2.9

|

3.5

|

F1

|

1500

|

2000

|

MY-5050G-XX

|

|

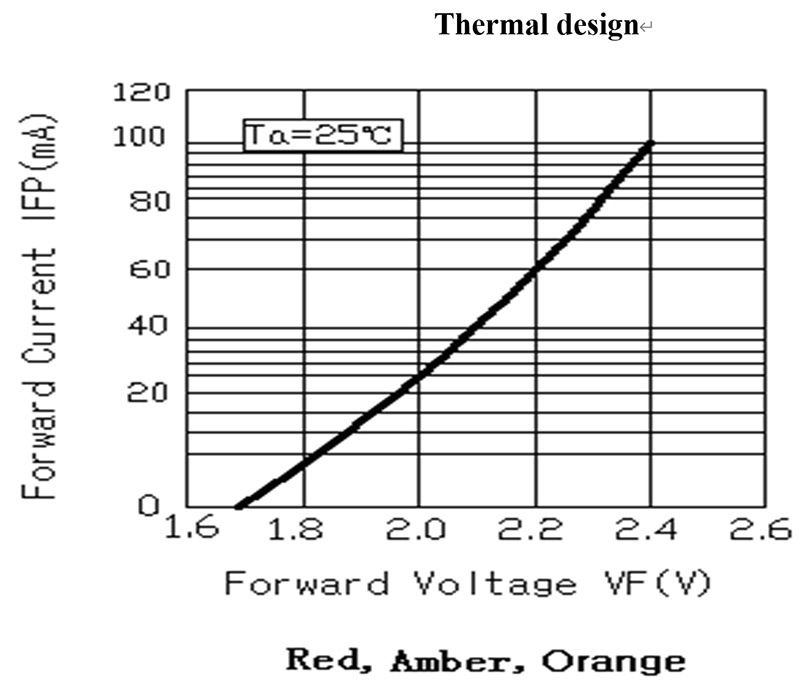

Amber

|

585

|

595

|

1.8

|

2.4

|

D2

|

900

|

1200

|

MY-5050A-XX

|

|

Orange

|

600

|

615

|

1.8

|

2.4

|

D2

|

900

|

1200

|

MY-5050O-XX

|

|

Red

|

620

|

635

|

1.8

|

2.4

|

D2

|

900

|

1200

|

MY-5050R-XX

|

|

P

|

395

|

400

|

3.0

|

3.4

|

D2

|

200

|

300

|

MY-5050R-XX

|

Note:

1. Please take Luminous Flux as standard parameter, Luminous Intensity is only for reference.

2.Tolerance of Luminous Intensity is ±15%.

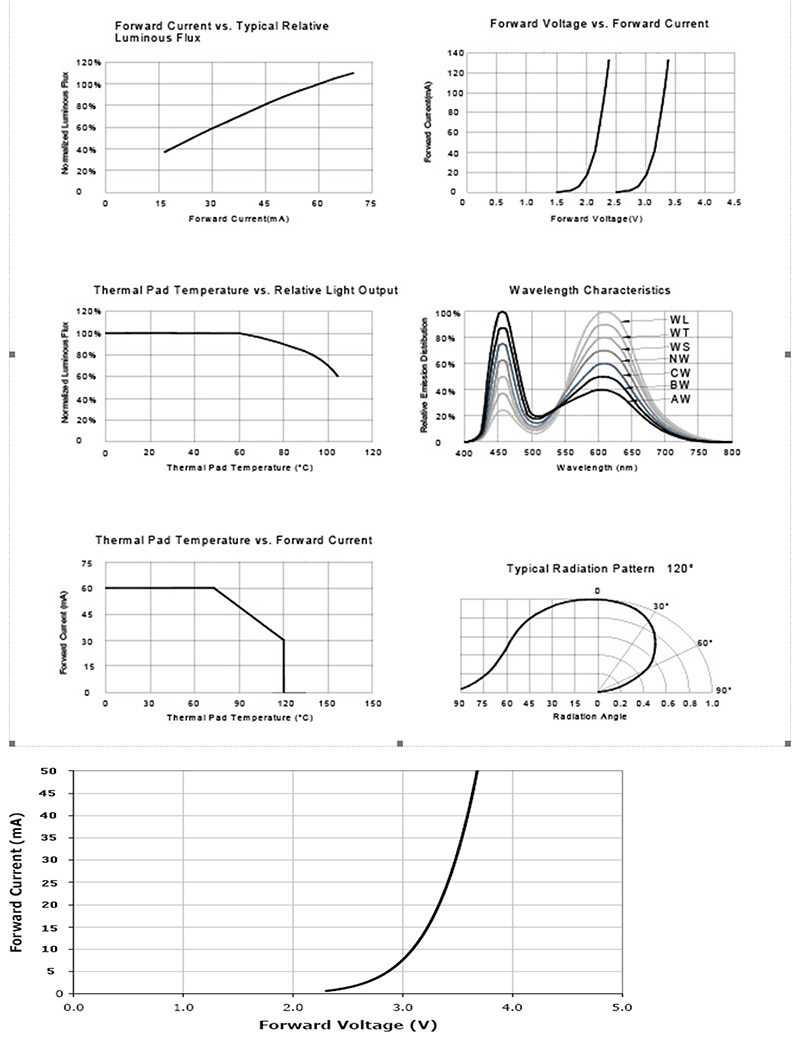

Directive Characteristics

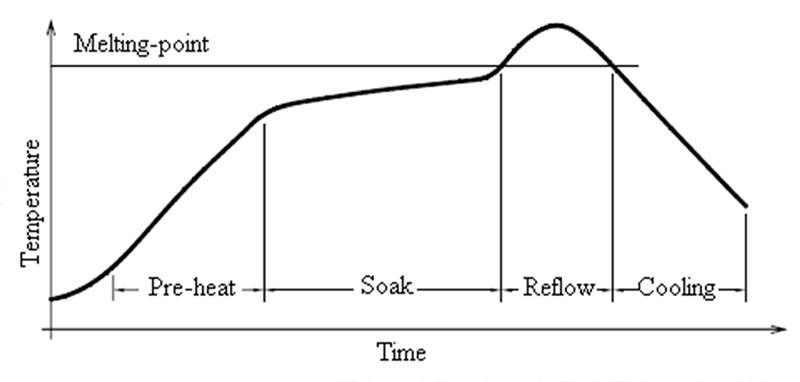

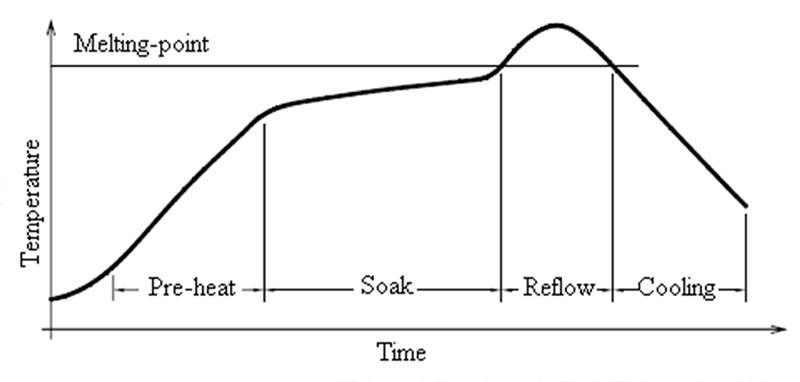

Reflow Temp/Time

Handing of an SMD LED 5050Should be done only when the Package has been cooled down to below 40℃ or less. This is to Prevent SMD LED 5050 failures due to thermal-mechanical stress during handing.

Reflow soldering

Temperature (top surface of the SMD LED 5050)profile:

1.Use with all SMDs

Solder=Sn63-Pb37

Average ramp-up rate= 4℃/sec.max.

Preheat temperature:100°~150℃

Preheat time =120sec.max.

Ramp-down rate = 6℃/sec.max.

Peak temperature = 230℃max

Time within 5℃ of actual peak temperature = 10 sec.max.

Duration above 183℃ is 60 sec.max.

2.Solder = Lead-Free

Average ramp-up rate = 4℃/sec.max

Preheat temperature:150~200℃

Preheat time =120 sec.max.

Ramp-down rate = 6℃/sec.max.

Peak temperature = 250℃ max.

Time within 5℃ of actual peak temperature =10 sec.max.

Duration above 217℃ is 60 sec.max.

Test circuit

Handling precautions

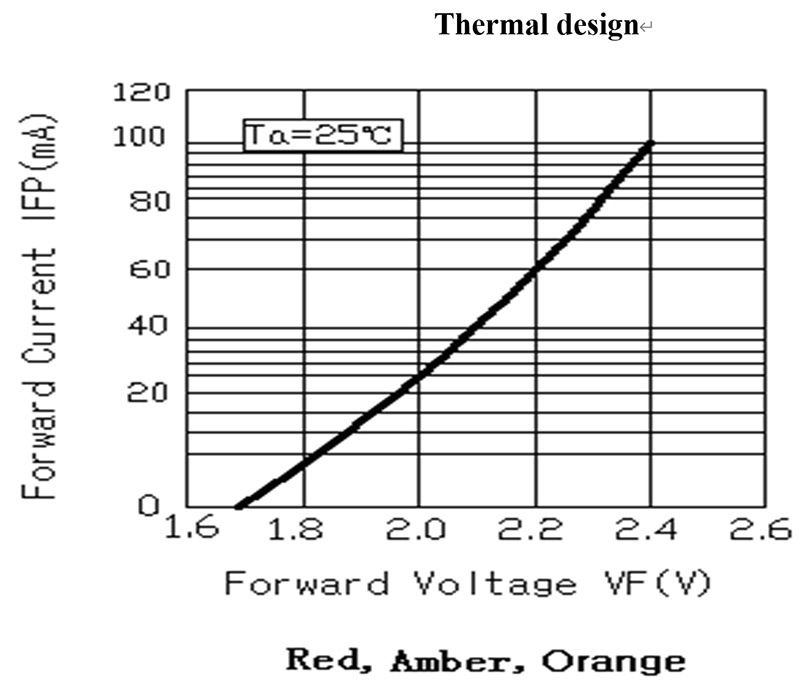

1. Over-current-proof

Customer must apply resistors for protection; otherwise slight voltage shift will cause big current change (Burn out will happen).

2.

2.1 When necessary, cleaning should occur only with isopropyl alcohol (IPA) at room temperature (25ºC) for a duration of no more than one minute. Dry at room temperature for 15 minutes before use.

2.2 The influence of ultrasonic cleaning on the SMD LED 5050 depends on factors such as ultrasonic power and the way the SMD LED 5050 are mounted. Ultrasonic cleaning should be pre-qualified to ensure this will not cause damage to the SMD LED 5050.

3. Storage

3.1 It is recommended to store the products in the following conditions

Humidity: 60% R.H. Max.

Temperature: 5℃~30℃(41℉~86℉): 5℃~30℃(41℉~86℉)

3.2 Shelf life in sealed bag: 12 month at <5℃~30℃ and <30% R.H. after the package is opened, the products should be used within 24hrs or they should be kept stored at ≦20% R.H. with zip-lock sealed.

4. Baking

It is recommended to bake before soldering when the pack is unsealed after 72hrs. The conditions are as followings:

4.1 80±3℃ x(10~12hrs) and <5%RH, taped reel type

4.2 100±3℃ x (1hr~2hrs), bulk type

4.3 130±3℃ x (45min ~1hr), bulk type