|

Feature

|

Applications

|

|

50W COB LED

|

Commercial Lighting

|

Package : TOP Package

(TOP)

|

Advertisement

|

Viewing Angle (2Θ1/2):120°

|

Architectural Lighting

|

Colloid Color: Yellow

|

Street Lamps

|

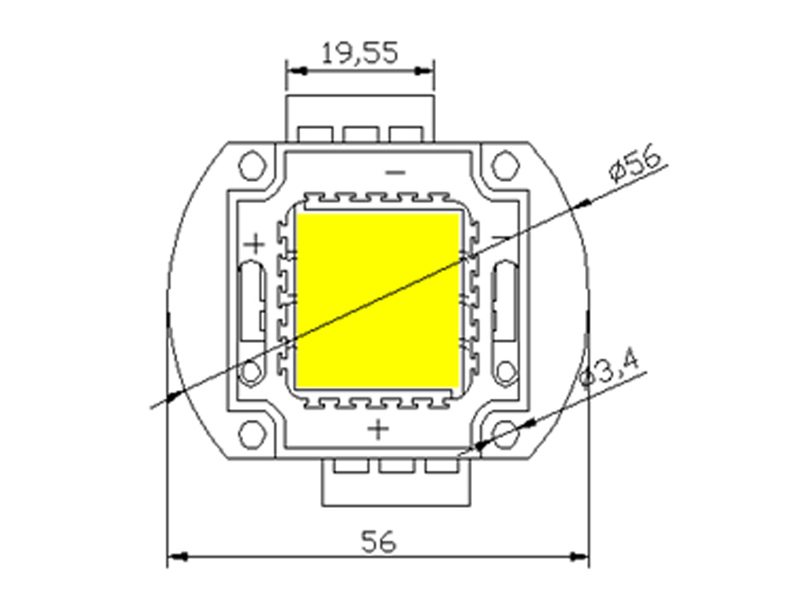

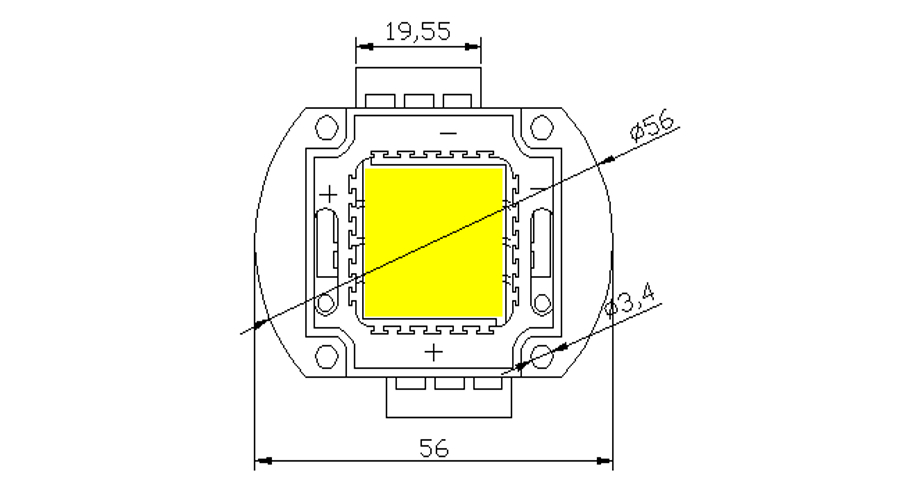

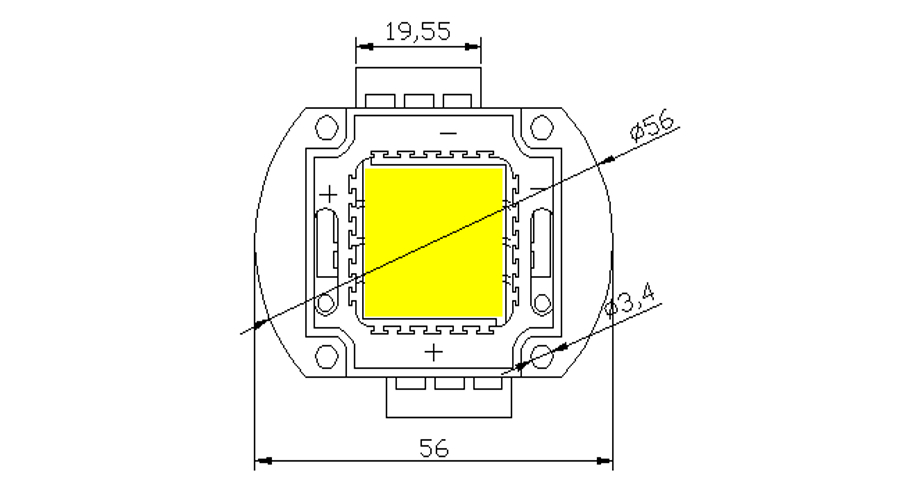

Package Dimensions

Notes:

1.All dimensions are in millimeters.

2.Tolerance is ±0.25 unless otherwise noted. (±0.25,)

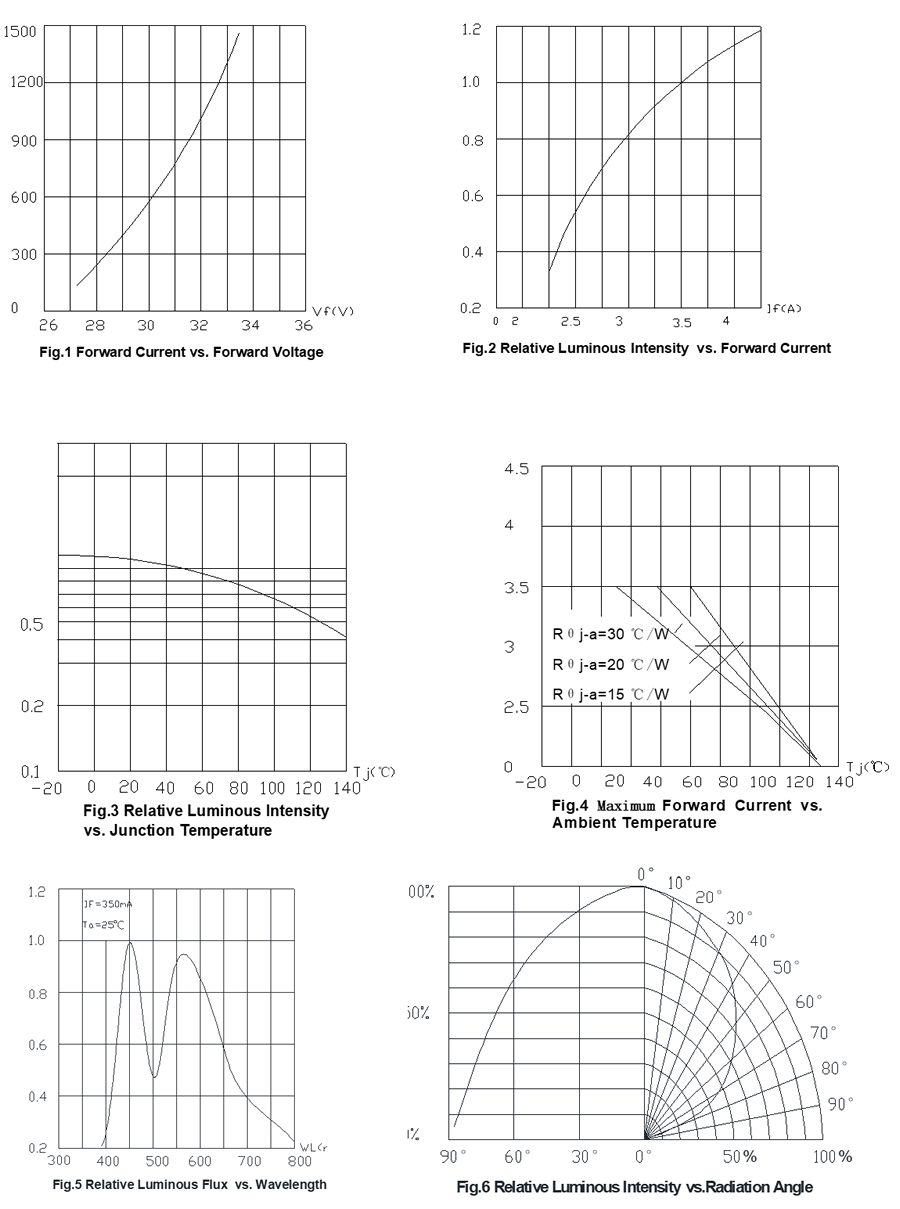

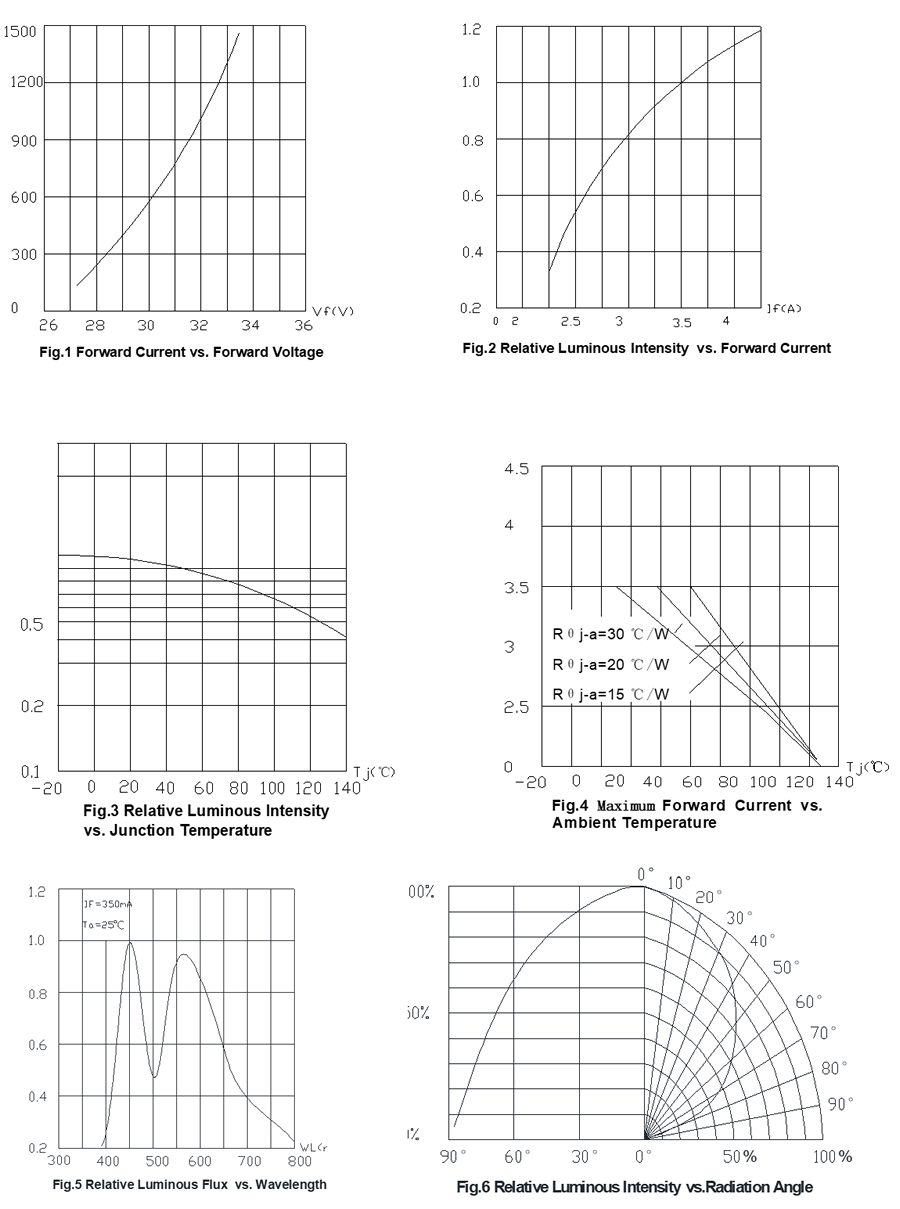

Electrical/Optical Characteristics (At TA=25°C)

|

Parameter

|

Symbol

|

Conditions

|

Min.

|

Avg.

|

Max.

|

Units

|

|

Luminous Intensity

|

Φ

|

IF=1.75A

|

5000

|

|

5500

|

lm

|

|

Color Temperature

|

CCT

|

IF=1.75A

|

6000

|

|

6500

|

K

|

|

Forward Voltage

|

VF

|

IF=1.75A

|

32

|

|

34

|

V

|

|

Color Rendering index

|

Ra

|

IF=1.75A

|

70

|

|

|

− −

|

Thermal Resistance Junction

To Board

|

RΘJ-B

|

IF=1.75A

|

|

10

|

|

°C/W

|

50% Power Angle

(50%)

|

2½

|

IF=1.75A

|

|

120

|

|

deg

|

|

Reverse Current

|

IR

|

VR=250V

|

|

|

5

|

μA

|

Absolute Maximum Rating(At TA=25°C)

|

Parameter

|

Symbol

|

Ratings

|

Units

|

|

Power Dissipation

|

PD

|

56

|

W

|

|

Continuous Forward Current

|

IF

|

1.75

|

A

|

|

Peak Forward Current [2]

|

IF(Peak)

|

5000

|

mA

|

LED Junction Temperature

(LED)

|

TJ

|

125

|

°C

|

|

Reverse Voltage

|

VR

|

250

|

V

|

|

Operating Temperature Range

|

TOPR

|

-30°C To +60°C

|

|

Storage Temperature Range

|

TSTG

|

-30°C To +60°C

|

|

Manual Soldering Temperature

|

TSOL

|

350°C± 20°C For 3 Seconds

|

|

Soldering on a heat plate

|

TSOL

|

190°C± 10°C For 20Seconds

|

|

ESD Sensitivity

|

ESD

|

2600V HBM

|

Important Notes:

1) Tolerance of measurement of luminous flux is ±10%.(±10%)

2) Tolerance of measurement of Vf is ±0.1 V.(±0。1V)

3) The product will be packaged in Anti-Static vacuum.

4) Please refer to High Power LED RELIABILITY TEST STANDARD for reliability test conditions.

(COB LED)

5) Use alcohl-based cleaning solvents such as isopropyl alcohol to clean the LED if necessary.

(,alcohl LED)

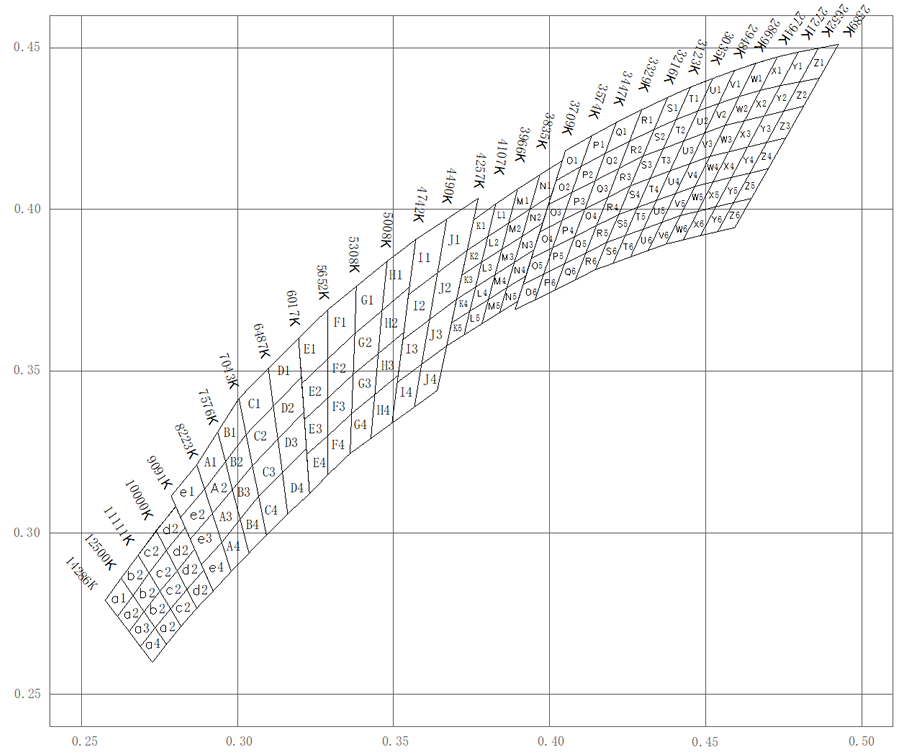

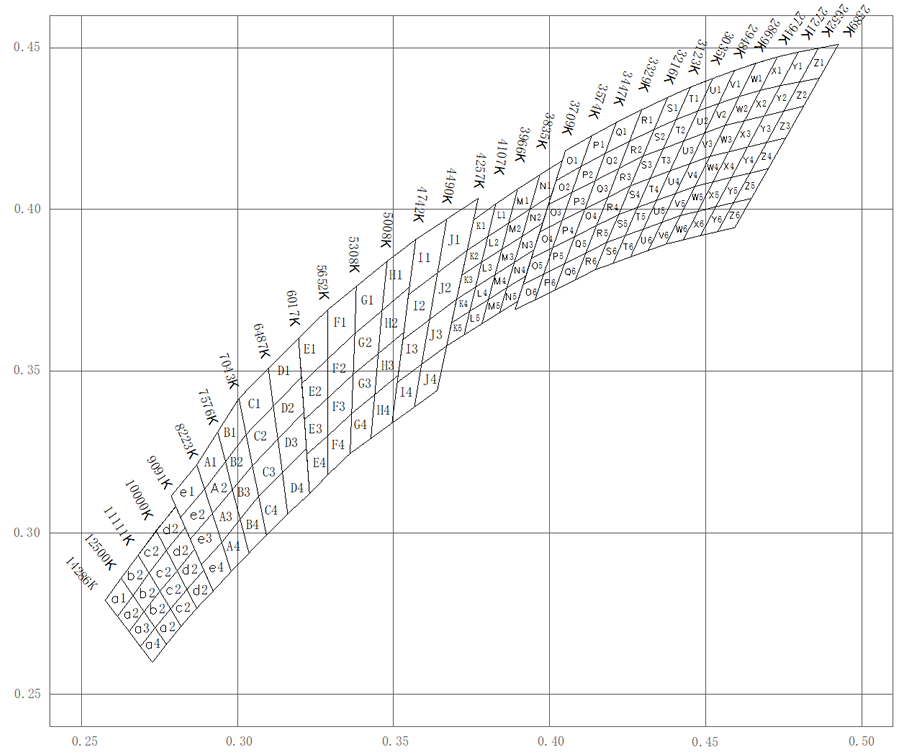

CIE Specifications (CIE)

Color Ranks(IF=1750mA,Ta=25℃)

a-d

Ranks

|

1

|

2

|

3

|

4

|

e-B

Ranks

|

1

|

2

|

3

|

4

|

|

0.2577

|

0.2803

|

0.2922

|

0.2728

|

0.2788

|

0.3004

|

0.3093

|

0.2922

|

|

0.2791

|

0.3081

|

0.282

|

0.2599

|

0.3114

|

0.3414

|

0.2993

|

0.282

|

C-D

Ranks

|

1

|

2

|

3

|

4

|

E-F

Ranks

|

1

|

2

|

3

|

4

|

|

0.3004

|

0.3196

|

0.3231

|

0.3093

|

0.3196

|

0.3381

|

0.3361

|

0.3231

|

|

0.3414

|

0.3602

|

0.312

|

0.2993

|

0.3602

|

0.3762

|

0.3245

|

0.312

|

G-H

Ranks

|

1

|

2

|

3

|

4

|

I-J

Ranks

|

1

|

2

|

3

|

4

|

|

0.3381

|

0.3571

|

0.3495

|

0.3361

|

0.3571

|

0.3771

|

0.364

|

0.3495

|

|

0.3762

|

0.3907

|

0.3339

|

0.3245

|

0.3907

|

0.4034

|

0.344

|

0.3339

|

K-N

Ranks

|

1

|

2

|

3

|

4

|

O-R

Ranks

|

1

|

2

|

3

|

4

|

|

0.3756

|

0.4041

|

0.3898

|

0.367

|

0.4051

|

0.4378

|

0.4147

|

0.3889

|

|

0.3967

|

0.415

|

0.3716

|

0.3578

|

0.4181

|

0.4346

|

0.3814

|

0.369

|

S-V

Ranks

|

1

|

2

|

3

|

4

|

W-Z

Ranks

|

1

|

2

|

3

|

4

|

|

0.4378

|

0.466

|

0.4373

|

0.4203

|

0.466

|

0.4924

|

0.4593

|

0.4373

|

|

0.4346

|

0.4452

|

0.3893

|

0.3833

|

0.4452

|

0.451

|

0.3944

|

0.3893

|

Measurement uncertainty of the color coordinates:±0.015(:±0.015)

Reliability

(1) Test Items And Condition

|

NO.

|

Items

|

Test Condition

|

Test Hours/Cycles

|

Sample Size

|

Ac/Re

|

|

1

|

DC Operating Life

|

Ta=25℃ IF=1.75A

|

1000H

|

50

|

0/1

|

|

2

|

Thermal Shock

|

-40℃/1H

+100℃/1H

|

50 Cycles

|

50

|

0/1

|

|

3

|

High Temperature Operation

|

Ta=80℃±5℃IF=1.75A

|

1000H

|

50

|

0/1

|

|

4

|

High Temperature/

High Humidity

(/)

|

80℃/80%RH

|

168H

|

50

|

0/1

|

|

5

|

Low Temperature

Operation

|

Ta=-40℃±5℃IF=1.75A

|

168H

|

50

|

0/1

|

|

6

|

ESD(HBM)

|

2000V HBM

|

1 Time

|

50

|

0/1

|

(2) Criteria For Judging the Damage

|

Items

|

Symbol

|

Test Condition

|

Limit

|

|

Min.

|

Max.

|

|

Luminous Intensity

|

IV

|

IF=1.75A

|

L.S.L*0.8

|

-----

|

|

Forward Voltage

|

VF

|

IF=1.75A

|

-----

|

U.S.L*1.1

|

|

Reverse Current

|

IR

|

VR=250

|

-----

|

U.S.L*2.0

|

Note():

L.S.L : Lower Standard Level

U.S.L : Upper Standard Level

CAUTIONS:

The 50W COB LEDs are devices which are materialized by combining Blue LEDs and special phosphors. Consequently the color of the LEDs is changed a little by an operating current. Care should be taken after due consideration when using LED’s.

(1) Moisture Proof Package:

When moisture is absorbed into the SMT package it may vaporize and expand during soldering .There is a possibility that this can cause exfoliation of the contacts and damage to the optical characteristics of the LEDs. For this reason, the moisture proof package is used to keep Moisture to a minimum in the package.

(2) Storage Conditions:

Before opening the package:

The COB LEDs should be kept at 30℃ or less and 60%RH or less. The 50W COB LEDs should be used with in a year. When storing the COB LEDs, moisture proof packaging with absorbent material (silica gel) is recommended.

After opening the package:

The 50W COB LEDs should be kept at 30℃ or less and 50%RH or less. The 50W COB LEDs should be soldered within 168 hours (7days) after opening the package. If unused COB LEDs remain, they should be stored in moisture proof packages, such as sealed containers with packages of moisture absorbent material (silica gel).It is also recommended to return the LEDs to the original moisture proof bag and to reseal the moisture proof bag again.

If the moisture absorbent material (silica gel) has faded away or the COB LEDs have exceeded the storage time. Baking treatment should be performed using the following conditions.

Baking treatment : more than 48 hours at 80±5℃/ 4h~12h (Humidity in accordance with the different environments)

(3) Heat Generation

Thermal design of the end product is of paramount importance. Please consider the heat generation of the COB LED when making the system design. The coefficient of temperature increase per input electric power is affected by the thermal resistance of the circuit board and density of COB LED placement on the board as well as other components.

The operating current should be decided after considering the ambient maximum temperature of COB LEDs.

(4)Cleaning

It is recommended that ethanol alcohol be used as a solvent for cleaning the COB LED ’s. when using other solvents, it should be confirmed beforehand whether the solvents will dissolve the package and the resin or not. Freon solvents should not be used to clean the COB LEDs because of worldwide regulations.。

(5) Static Electricity

Static electricity or surge voltage damages the 50W COB LEDs. .

It is recommended that a wrist band or an anti-electrostatic glove be used when handling the 50W COB LEDs. All devices, equipments and machineries must be properly grounded. It is recommended that measures be taken against surge voltage to the equipment that mounts the COB LED’s .When inspecting the final products in which COB LEDs were assembled. It is recommended to check. Whether the assembled 50W COB LEDs are damaged by static electricity or not. It is easy to find Static-damaged COB LED’s by a light –on test or a VF test at a lower current (below 20 mA is recommended). Damaged COB LEDs will show some unusual characteristics such as the leak current. Remarkably increases, the forward voltage becomes lower , or the COB LEDs do not light at the low Current.